Stage 1

Visual Inspection

Even if completely burnt out or the casing has been broken we are able to use our purpose built facilities to bring the unit back to original standard

Stage 2

Pre-Disassemble Test

The unit is fully tested, to make sure it is truly at fault. We receive many units condemned by garages, that outside of looking a little worn, function perfectly.

We don't want to charge for a problem that doesn't exist.

Stage 3

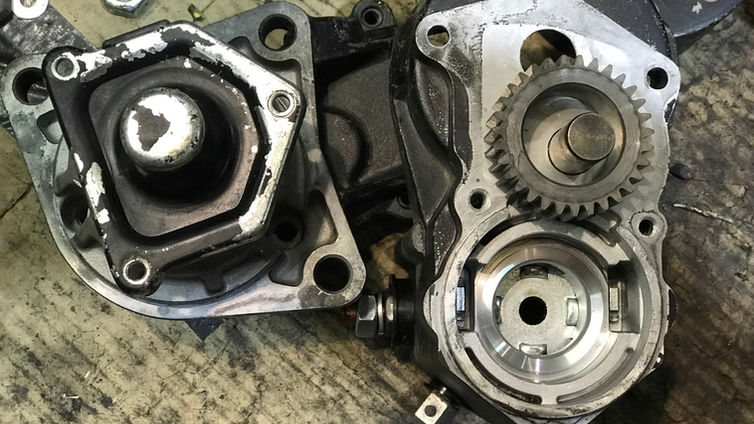

Unit Disassemble & Clean

The Unit is completely stripped down and old components are removed. Each unit is then thoroughly cleaned and shot-blasted, to remove any defect prior to replacement parts being fitted.

Stage 4

Component Replacement

All faulty components are replaced, with new components fitted into the freshly prepared unit

Stage 5

Unit Stress Test

With new parts fitted, the unit is subjected to a rigorous stress test. Not only to see if it is fully functional, but to test if it is capable of performing under load, in order to simulate it being fitted to the recipient vehicle.

Stage 6

Surface Preparation

All components are masked and the unit is painted with heat resistant paint, to act as a barrier to corrosion and to stop adhesion of dirt to the unit, it also helps the unit look as good as new.

Stage 7

Final PDI

The unit is passed through quality control, to ensure any sub-standard work is captured and rectified, as part of the company's quality management framework.

Stage 8

Dispatch

Each unit is labelled and sealed, either for collection or delivery, by our same day courier.